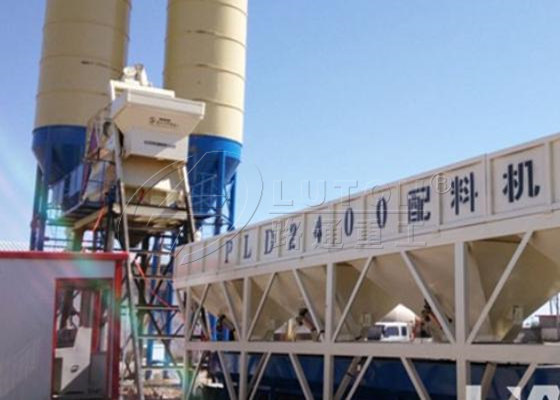

How To Ensure The Accuracy Of Aggregate Weighing In A Concrete Mixing Plant

Ensuring the accuracy of aggregate weighing is crucial in concrete mixing plants, as it directly affects the quality of the final concrete. The following are some key measures to ensure the accuracy of aggregate weighing.

Selection of High-precision Sensors And Scales

The mixing plant should choose sensors and scales with high precision and stability. These devices should be able to accurately and quickly respond to changes in the weight of aggregates, ensuring the accuracy of weighing.

Regular Calibration And Maintenance

Sensors and scales need to be calibrated regularly to ensure their accuracy is not affected by time and usage conditions. At the same time, necessary maintenance and upkeep of the scale body, such as cleaning and fastening loose parts, are also key to maintaining weighing accuracy.

Double Hole Feeding System

In order to avoid the potential blockage problem caused by single hole feeding, some advanced mixing stations adopt a double hole feeding design. This can evenly distribute the aggregates in the hopper and improve the accuracy of weighing. As the target weight is approached, the feeding port gradually closes to prevent insufficient aggregate.

Automatic Control System

Mixing plants are usually equipped with an automatic control system that can monitor and control the weighing process of aggregates in real time. By introducing precise weighing sensors and control systems, aggregates can be accurately weighed and automatically replenished when needed.

Independent Weighing Hopper

When the mixing plant is equipped with multiple batching bins, each bin should use an independent weighing hopper. This can avoid the mutual influence of errors between different silos and ensure that the weighing of aggregates in each silo is accurate.

Employee Training And Management

Operators should receive relevant training and be familiar with the operation and maintenance of the weighing system. At the same time, the mixing plant should establish a strict management system to ensure the standardization and normalization of the weighing process.

In summary, measures such as selecting high-precision equipment, regular calibration and maintenance, optimizing the feeding system, introducing an automatic control system, using independent weighing hoppers, and strengthening employee training and management can ensure the accuracy of aggregate weighing in concrete mixing plants.